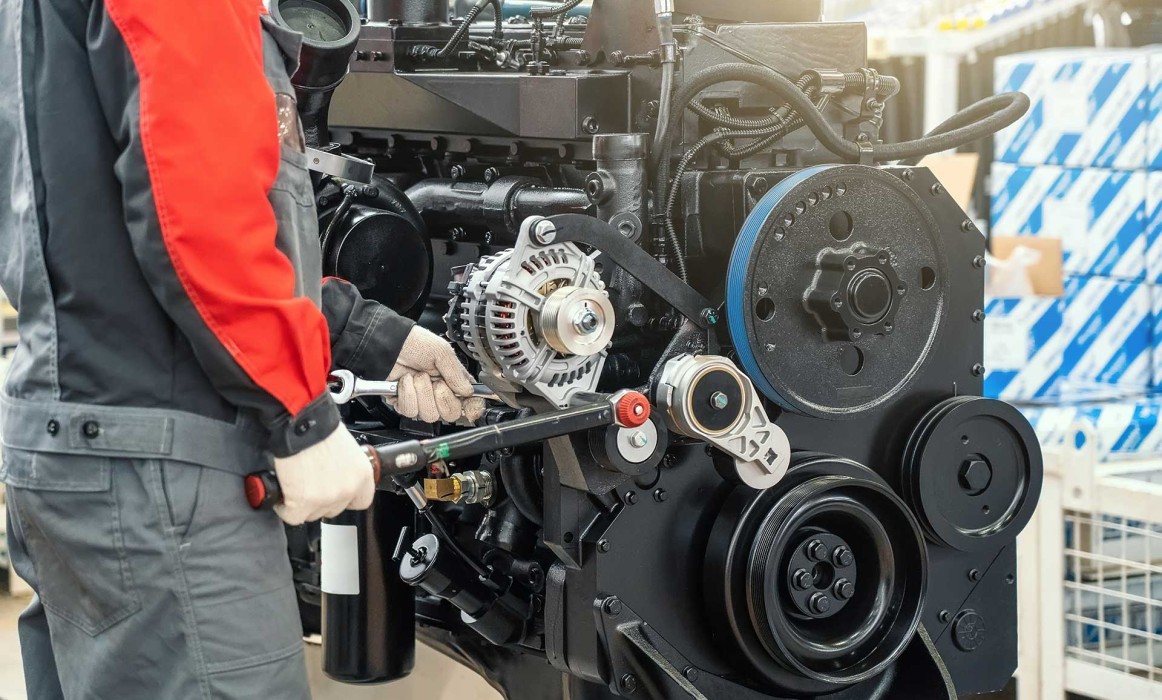

Agricultural tractors are equipped with powerful engines that form the basis of daily operations. Engine maintenance plays a critical role in ensuring the efficient operation of the tractor and achieving long-lasting performance. In this article, we will focus on important tips for performing maintenance on agricultural tractor engines.

How to Perform Tractor Engine Maintenance?

Consider the following tips for tractor engine maintenance:

Regular Oil Changes

Oil, one of the most important components of the engine, reduces friction and protects engine parts, thereby improving performance. Regular oil changes ensure that the oil remains clean and effectively performs its function. Changing the oil at the frequency specified by the manufacturer helps maintain the long-term health of your engine.

Air Filter Replacement

The air filter provides clean air to the engine, optimizing the combustion process. Dirty air filters can reduce performance and expose the engine to increased wear. Regularly replacing the air filter ensures that the engine receives clean air, resulting in efficient operation.

Cooling System Checks

The cooling system should be regularly checked to prevent the engine from overheating. Radiator coolant levels, antifreeze concentration, and the proper operation of the cooling fan should be regularly inspected. Overheating can cause damage to engine parts, making regular checks on the cooling system vital.

Fuel Filter Replacement

Clear fuel ensures that the engine operates smoothly and efficiently. Dirty fuel filters can clog injectors and affect the combustion process. Regularly replacing the fuel filter will improve your engine's performance and keep the fuel system clean.

Cylinder and Piston Checks

Cylinders are important components that affect engine performance. Cylinder walls and pistons should be regularly checked and cleaned or replaced if necessary. Proper cylinder operation ensures that the engine runs smoothly and efficiently.

Distributor and Ignition System Checks

The ignition system ensures that the engine runs at the correct time. The distributor plays a critical role in this system. Therefore, distributor caps and spark plugs should be regularly checked. Deficiencies or contamination can adversely affect engine performance.

Belt Checks

Belts that connect various engine components should be properly tensioned. Loose or worn belts can hinder the engine's efficient operation. Regularly checking and replacing belts as needed for engine maintenance ensures that the engine runs strong.

Fuel Injector Cleaning

Fuel injectors spray fuel into the cylinders. Dirty or clogged injectors can prevent fuel from being evenly distributed. Regular injector cleaning ensures the efficient operation of the fuel injection system.

Exhaust System Checks

The exhaust system manages the engine's combustion byproducts, allowing them to be expelled without harming the environment. Therefore, the exhaust system should be regularly checked and cleaned if necessary. Leaks in exhaust gases and corrosion in the exhaust pipe can hinder the engine's effective operation.

ECU (Engine Control Unit) Software Updates

In modern tractors, the ECU or engine control unit monitors various parameters to optimize engine performance. Software updates provided by the manufacturer can improve engine efficiency and enable new features.

Engine Heating and Cooling Controls

The heating system should be regularly checked to ensure that the engine operates effectively in cold weather. Regularly checking the cooling system also prevents overheating issues.

Oil Level and Quality Checks

Regularly checking oil levels and adding oil as needed helps maintain proper oil pressure in the engine. The quality of the oil is also important. Regular oil analysis helps understand what's happening inside the engine and take necessary action.

Turbocharger Checks

The turbocharger increases engine performance by providing more air. Regularly checking the turbocharger, including air filters, air sensors, and vacuum hoses, ensures its proper operation.

Intake and Exhaust Manifolds

The intake manifold and exhaust manifold regulate airflow into the combustion chamber and outwards. Clean and leak-free manifolds ensure the engine operates efficiently.

Engine maintenance is vital for the durability and strong performance of agricultural tractors. By following these tips for regular maintenance, tractor engines can be kept strong and long-lasting. Farmers can achieve continuous and reliable performance in agricultural operations by prioritizing engine maintenance.

en

en  tr

tr