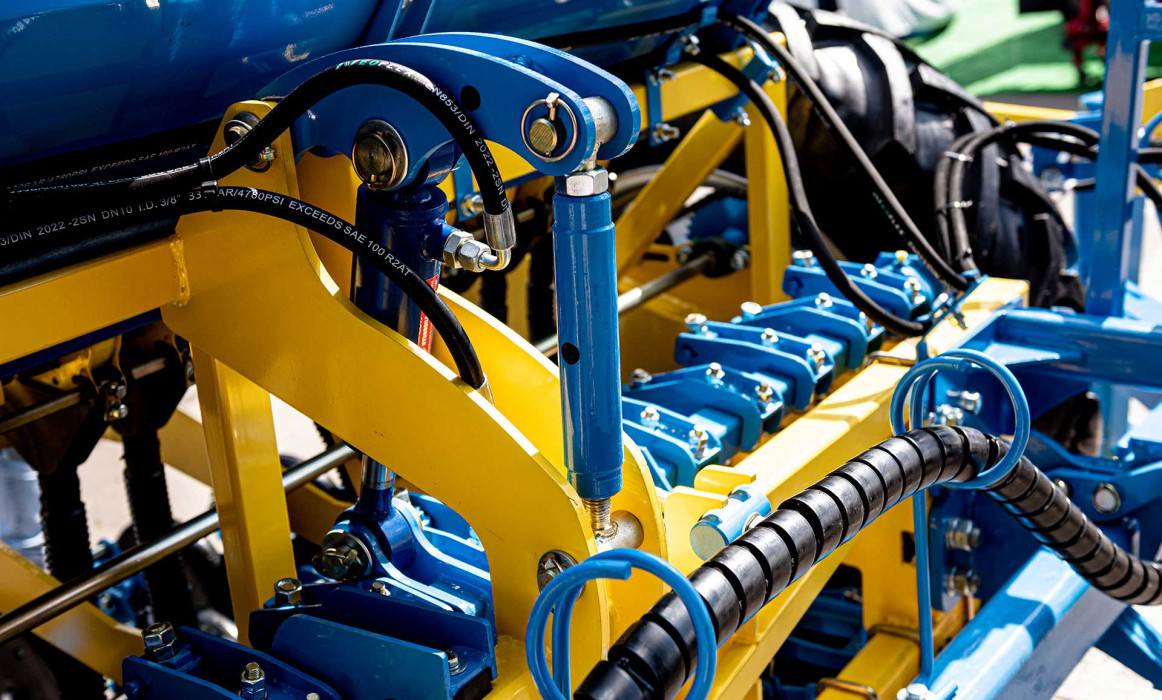

Tractor hydraulic systems facilitate the movement of various implements and accessories. Hydraulic cylinders are therefore important components of tractor hydraulic systems. It is therefore important for tractor owners to understand the selection, installation and maintenance of tractor hydraulic cylinders.

What are Tractor Hydraulic Cylinders?

Tractor hydraulic cylinders are key components that facilitate mechanical movement in tractors using hydraulic power. These cylinders convert linear motion using pressurised fluid power provided by the hydraulic system.

Tractor hydraulic cylinders generally have a basic structure that includes a piston and a cylinder tube. The piston is a tube that can move within the cylinder. Hydraulic fluid pressure allows the piston to move. The cylinder tube is a cylindrical tube in which the piston moves. It contains seals that allow the piston to move back and forth.

Tractor hydraulic cylinders are important parts that increase the functionality and efficiency of the tractor. Proper maintenance and regular checks will ensure that the hydraulic cylinders work reliably and have a long life.

What to Consider When Choosing a Tractor cylinder?

The selection of a tractor hydraulic cylinder should be made carefully to ensure the correct performance and fit. The following factors should be considered when making a selection:

- Load capacity: The cylinder must have sufficient capacity to support the weight of the load to be carried. This should be determined based on the application in which the tractor will be used.

- Stroke length: The stroke length of the hydraulic cylinder must be sufficient to move the required implement. This may vary depending on the design and function of the implement.

- Dimensions: The hydraulic cylinder should be selected with the correct dimensions to fit the tractor's existing hydraulic system.

- Quality and durability: Selecting a hydraulic cylinder that is made from high quality materials and is durable is essential for long and reliable performance.

How to Install Tractor Hydraulic Cylinders?

The installation of tractor hydraulic cylinders requires the correct procedures to be followed. The following are general steps for installing tractor cylinders:

- Preparation: First, safely stop the tractor and apply the parking brake before starting the installation. Move the control levers to relieve pressure from the hydraulic system and stop the engine.

- Check the equipment: Check that the hydraulic cylinders and mounting accessories are correct. Check for damage or wear.

- Mounting position: Determine where the cylinder will be mounted. Correct positioning of the cylinder is essential for proper operation.

- Connections: Connect the cylinder to the tractor's hydraulic system. If necessary, seal with gaskets and connectors. Ensure that all connections are tight, but take care not to over-tighten.

- Adjust the cylinder: Make the necessary adjustments to align the cylinder with other tractor components. If necessary, use adjustable couplings to adjust the length or position of the cylinder.

- Checks: After installation, check the hydraulic system. Ensure that the cylinder operates correctly and performs the desired function. If necessary, check for leaks in the hydraulic system and repair them.

- Test: After installation, drive the tractor and test the function of the hydraulic cylinder. Ensure that the cylinder moves correctly and provides the desired power or movement to the tractor.

How to Maintain Hydraulic Cylinders?

Regular maintenance of hydraulic cylinders will maintain their performance and extend their life.

Here are some important points to remember when maintaining tractor hydraulic cylinders:

- Cleaning and lubrication: Regularly clean dust, dirt and residue from hydraulic cylinders. Also lubricate the cylinder surfaces with a suitable lubricant to reduce friction.

- Check for leaks: If there are any leaks in the hydraulic cylinders, check immediately and make any necessary repairs. Leaks can cause loss of efficiency and reduced performance in the hydraulic system.

- Rod inspection: Check the rod and joints of the hydraulic cylinder regularly. Make necessary repairs or replace parts if they show signs of wear, looseness or damage.

- Hydraulic oil level: Regularly check and adjust the hydraulic oil level to suit the tractor's hydraulic system. The correct oil level ensures smooth operation of the hydraulic cylinder.

- Professional maintenance: It is important to have a professional carry out general maintenance on the tractor's hydraulic cylinders at regular intervals. Specialists can detect potential problems in the hydraulic system and carry out preventive maintenance.

en

en  tr

tr