CMM measuring device is also known as coordinate measuring device. The device consists of the initials of the words "coordinate measurement machines". This device, which we use in the quality control and testing process, consists of hardware and software components designed to take 3D measurements.

What is CMM?

The CMM measuring device is a coordinate measuring system. This system makes measurements according to the Cartesian coordinate. It moves in the X, Y and Z axis. The head connected to the probe rotates 360 degrees on its own axis, offering versatile measurement opportunities.

The CMM benches we use in our factory during the quality control and testing phase have high precision in dimensional measurements. Measurements can be made with a precision of 1 micron or even less. In this way, errors that occur in production are noticed during the quality control process and these errors are eliminated before they reach the customer.

What are the Types of CMM Meter?

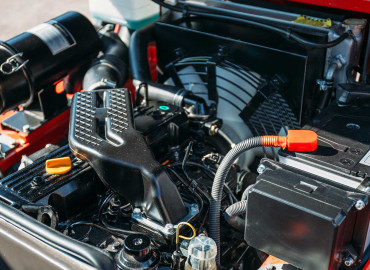

Three-dimensional measuring devices (coordinate measuring devices) basically consist of main components such as body, register and slides, control unit, servo motors, electronic rulers, probing system, software, computer hardware. There are different coordinate measuring devices according to their usage areas.

The types of CMM meter are as follows:

Classic (Fixed)

The first CMM measuring device was produced in the early 1960s. This machine produced is a simple device that reads a digital value that displays the X,Y,Z position. Classic CMM types include bridge, support, and ramp components. Fixed coordinate measuring devices have very high levels of precision. They also provide a link to the CAD model. However, it does require the part to be brought to the machine and the part to fit within the CMM measuring grid.

The stationary CMM machine is quite complex to use. Therefore, this situation limits the number of potential operators and users.

Portable Coordinate Measuring Device

Portable CMM measuring device has more advantages and flexibility than conventional coordinate measuring devices. Their weight is low. Therefore, they can be used wherever measurements are required. While the part should be taken to the machine in classical machines, the machine can be taken to the part in portable machines. There is no need to create a controlled environment for its use. It is also quite simple to use. They provide highly accurate results. It is also much cheaper than conventional CMM measuring devices.

Articulated Arm

The articulating arm CMM measuring device determines and records the position of the probe in the 3D environment. It then reports the results through the software. To calculate the stylus position, the angle of rotation of each attachment point on the arm and the length of each segment must be known. In the most open position, the radial reach typically ranges from 60 cm to 182 cm.

The angle of rotation of each movable joint within the arm is determined using optical rotary encoders. These encoders incrementally determine the number of turns by detecting precisely drawn lines on a glass disk. Arms typically have 6 or 7 axes of rotation. This allows the device to move in many different ways.

Laser CMM Measuring Device

The laser coordinate measuring device is very easy to operate. Two angles and a distance meter form the basis of the use of this device. Laser measuring device is of two types, interferometer and absolute distance meter (ADM).

The laser tracker sends a laser beam to a retroreflective target held on the object to be measured. The beam reflected from the target retraces the path it came from and returns to the device from the point where it came out. When the beam returns to the device, it is transmitted to a distance measuring system that measures the distance between the device and the SMR.

The laser tracker has extremely high accuracy levels and a much wider measuring range. It collects coordinate data at very high speeds. It can also be operated by only one operator.

en

en  tr

tr