The long-lasting performance of your hydraulic machines depends on the quality of the hydraulic fluid you use. Therefore, attention should be paid to the hydraulic system, application and viscosity grade. First of all, the most confusing part of this entire chapter is that there are so many different types of hydraulic oil. But with some tips you can choose the best hydraulic fluid for your machine.

Things To Consider When Choosing Hydraulic Oil

When it comes to hydraulic oil selection, two basic things need to be considered. These, hydraulic oil type and viscosity grade. In addition to the specified characteristics, the type of hydraulic pump installed in the system and the application and oil selection should also be determined. There are also many other factors required to make the right choices, such as the type of base oil, overall oil quality and performance characteristics. Therefore, knowing all the necessary factors that affect hydraulic oil performance will make your choice much easier.

Viscosity Requirements

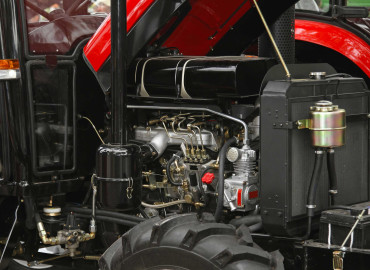

The first thing required in the hydraulic oil selection process is pump design types and viscosity grades. Hydraulic systems are equipped with three main pump designs: vane, gear and piston. Basically, pump designs are developed for specific activities and tasks. Therefore, they are different from each other.

- Vane Pump: The vane pump is designed with rotors with slots arranged around the rotating shaft. It provides smooth operation and low noise, although the pressure capacity is somewhat low. At the same time, vane pumps are relatively expensive compared to other pumps. However, it compensates for this by providing a constant flow.

- Piston Pump: Pumps for hydraulic machines are of fixed or variable displacement type. The piston pump falls under the variable category and is a mid-range hydraulic pump. This type of pumps are more durable than vane pumps. At the same time, it can do heavy industry works as it produces 6,000 psi high pressure.

- Gear Pump: Gear pump is basically of two types. They are internally and externally threaded. Both fall into the fixed displacement category. In addition, gear pumps are simple and are used in most hydraulic machines. They are economically suitable for everyone's needs as they require less maintenance than other pump types.

There are two main types of gear pumps. These are external and internal threaded. While the external pump internal gear is usually found on automotive hydraulic oil pumps, it is activated by two gears that push and push the oil out of the gear. They are set up differently. An external gear rotor is connected via the internal gear for its operation. They have gear pumps that are easy to maintain. However, there is a limited viscosity range up to 300 cSt. The internal gear offers a wide range of viscosities up to 2,200 cSt. In this way, the pump produces high pressures up to 3,500 psi, ensuring high efficiency and trouble-free operation.

Types of Oil

There are various types of lubricants available, depending on the applications. Therefore, choosing the appropriate oil can become a difficult task. Therefore, it would be best to consider a few tips suggested by experts to help you choose the right oil. Hydraulic oil types are as follows:

- Anti-Wear Oil: Zinc Dialkyl Dithiophosphate is used as anti-wear oil and hydraulic oil, mostly used in engine, to maintain lubrication.

- Monograde Oil: When the hydraulic system requires low temperature, it uses monograde or multigrade oil. This helps the application maintain its viscosity grade.

- Detergent Oil: Detergent oils are best suited for mobile hydraulic system as they are smaller in size. The best advantage of detergent oil is that it emulsifies the water content.

It is possible to choose the most suitable fluid for your machine by paying attention to viscosity requirements and oil types. In this way, you can maximize the efficiency of your machine.

en

en  tr

tr