It is possible to use tractors, which are extremely useful, for many years with the right maintenance. Since there are many different tractors, maintenance routines also differ from tractor to tractor. However, there are basic maintenances that are necessary for you to use it for many years without any problems. You can find general information about tractor maintenance in our article.

Tractor Maintenance

The basic maintenances you can do for your tractor are listed below.

Regular Inspection

- Visual control,

- Light test,

- Checking the tire pressure,

- Inspection of belts and hoses,

- Testing the hydraulic system,

- Changing the air filter

Visual Control

Before you start any scheduled maintenance on your tractor, you should check everything for anything that looks worn, broken or dirty. In this way, you minimize the possibility of missing something.

Light Test

Some tractors may not have any lights. However, some have a comprehensive lighting system that includes turn signals and interior lighting. Each of the existing lights should be checked after each use. In this way, you will notice electrical problems, if any. If a light is not working, there may be a bulb or fuse that needs replacing.

Checking Tire Pressure

Check the tire pressure using the tire pressure gauge. Make sure to compare the value obtained with the value written on the sidewall of the tire.

Tractor tires are parts that can last for years. However, under-inflating the tires causes faster wear and damage to the tires. It also leads to an increase in fuel consumption.

Tires lose pressure more quickly in hot weather. For this reason, it is necessary to check the tire pressure more frequently from time to time.

Inspecting Belts and Hoses

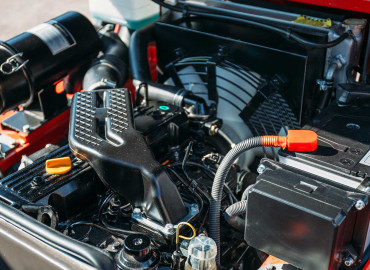

The tractor's engine is based on a set of rubber hoses and belts. Therefore, you should check the rubber components for any wear or damage. If there is any wear, you should definitely replace it.

Testing the Hydraulic System

Special tools are needed to control the hydraulic system of the tractor. If you do not have the necessary tools, you must have the hydraulic system serviced after every 500 hours of use.

Changing the Air Filter

The air filter needs to be changed at different intervals depending on the environment in which the tractor is used. Filters should be replaced when they appear dirty. After 8 hours of use, you can check the air filters and decide whether to replace them.

Checking and Changing Fluids

Checking and changing fluids, which are among the tractor maintenance practices include;

- Checking oil level,

- Checking oil level the radiator fluid level,

- Checking oil level hydraulic fluid

Checking the oil level: After waiting for a few minutes for the tractor to be started and warmed up, the dipstick is removed, wiped and remounted to the engine. Then the dipstick is removed and the oil level is checked. If the oil level is low, you should add oil or change the oil if the time has come. It can be particularly dangerous to perform these operations on tractors with mowers while they are operating. For this reason, the tractor should not be running while the tractor is being maintained.

You should change the oil every 100 hours. But different tractors are designed to run at different times between oil changes. Therefore, you can get it from the user manual to find out the oil change time.

To change the oil, the drain plug must be removed from the oil pan and the oil must be drained into a suitable container. After the oil has been drained, replace the drain plug and remove the oil filter. Install the new oil filter and fill in the appropriate amount of oil (as specified in the owner's manual).

Checking the radiator fluid level: It is normal for the coolant and water level in the radiator to decrease over time. Therefore, it must be completed at regular intervals. Therefore, the fluid level should be checked regularly. Checking the liquid level periodically will allow you to detect leaks in the cooling system early.

Changing the hydraulic fluid: It is best to have it replaced by a professional, as changing the hydraulic fluid requires the use of special tools.

en

en  tr

tr